Folding chair legs spread and the seat fell down

When a person was sitting on a folding chair, rivets fixing the metal seat support frame fractured and the chair collapsed. Then, the person landed hard on the backside and the floor was also damaged. It was inferred that the rivets had insufficient strength. The following shows details of the case.

Details of the inquiry

Four years ago, I bought a folding desk and a folding chair in a set. When I was sitting on the folding chair for 30 minutes or so, I suddenly heard sounds like glass breaking when the chair legs fully spread and the chair collapsed. I landed hard on my backside with the seat, and my body was thrown on the floor. I got a strong pain in my bottom.

Observing the broken chair, I found out that rivets on the right and left sides fixing the seat support frame to the pipes had burst. I gathered up and observed the parts. Rivets1 on the right and left sides were disconnected at the hollow portion which had been swaged at the end. The product label attached to the chair did not indicate a withstand load. I would like to request for an investigation to see if there's any safety problem in the product. The wood floor of my rented house was damaged by the impact of the collapsed chair. I want the chair manufacturer to pay the repair cost.

- 1 JIS B0101 "Screw threads and fasteners - Vocabulary": A rivet consists of a smooth cylindrical shaft and a head on one end. The shaft is inserted into a drilled hole of objects to be fastened, and the tail (the end opposite to the head) is swaged so that the objects are fastened.

Product test and investigation

After receiving the above inquiry, the local consumer center (hereinafter called "center") requested NCAC for a product test. The rivets used for the product under complaint had a hollow end. However, the center heard from the original seller of the chair that the rivets with a hollow end had been replaced by full solid rivets. Even the original seller didn't have any product equal to the product under complaint. Therefore NCAC conducted a visual check of the fracture cross section of the rivets used for the product under complaint as well as a loading test of the same type product with full solid rivets. As a result, NCAC found out the following details.

(1) Overview of the product under complaint

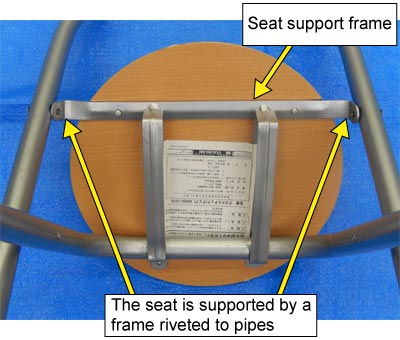

The product under complaint had a seat support frame (hereinafter called "frame") riveted to pipes on the right and left sides. The product label attached to the chair did not indicate a withstand load (See Photo 1).

Photo 1: Appearance of the product under complaint

(the seat was temporarily fastened)

(2) Visual check of the product under complaint

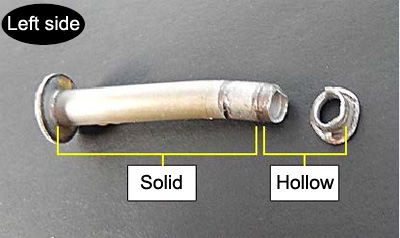

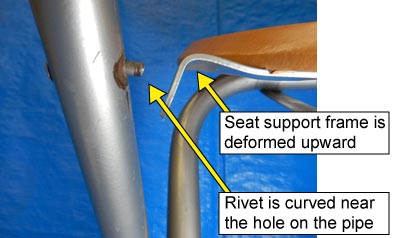

The riveted frame was distorted upward on its left side. The end of each rivet on the right and left sides of the seat was disconnected and the shaft of each rivet was curved. The hollow part of the rivet was positioned at the joint of the frame and the pipe, so it was inferred that a shear load2 had been applied to the hollow part and then the rivet had been broken (See Photo 2 & 3).

- 2 A sear load is a force that is applied at right angle to the shaft of a screw, a bolt, etc.

Photo 2: Appearance of the rivet of the product under complaint

Photo 3: The product under complaint; the frame distorted upward and the rivet curved at the end

(3) Appearance check of the same type product

The swaged portion of rivets of the same type product was solid, while that of the product under complaint was hollow. Each rivet of the same type product was oriented against the direction of that of the product under complaint: the head was inside the chair and the swaged end was outside the chair. Therefore, all the spots applied with a large shear load between the frame and the pipe were solid (See Diagram below).

Diagram: Dimensions of the rivet of the product under complaint and of that of the same type product

(4) Measuring of dimensions of the rivet and the seat support frame

Dimensions of the rivet used for the product under complaint and of the rivet used for the same type product were measured. It was found out that the hollow part of the rivet of the product under complaint (outer diameter: 4.9 mm, hole diameter: 3.5 mm, wall thickness: 0.7 mm) (See Diagram above) was not resistant to a large shear load.

(5) Load test of the product under complaint

In order to investigate strength of the rivet and of the frame used for the same type product, a load test was conducted, referring to the clause 7.1 Static strength test of seating face3, JIS S1203:1998 "Furniture - Chairs and stools - Determination of strength and durability". Based on the standard, the load 2000N, the maximum load specified in the list of classified tests, was applied 10 times repeatedly at the speed of 2 mm per second. After the load test, the rivets and the frame of the same type product showed little deformation, and the rivets did not fractured.

- 3 A force is vertically applied downward for 10 seconds or more at the position set by the load positioning jig (an auxiliary tool guiding to a proper position) and at 100 mm from the front edge of the seating face using a pressure equalizing plate (a rigid plate with a smooth and hard surface). It is repeated 10 times at each position.

Summarized outcome

The center orally conveyed the product test results to the inquirer. The inquirer and the seller discussed the matter and reached a conclusion that the seller would cover the product price, the floor repair cost, and the medical expense.